Dear friends/clients,

Covid-19 has devastated our economy, but since the start of 2021 we have seen signs that the pandemic is becoming contained in Australia and received the good news that the long-awaited vaccinations have begun, so we can begin the process of rebuilding our businesses, our economy, our normal life.

One of our biggest problems that we at DPPP are likely to face is supply. With most of our materials and papers coming from overseas, long delays in freight look set to prove challenging for a return to normality.

Most of you receiving this newsletter are regular clients, however there are some that we haven’t heard from for a while. This is a plea that we should support each other and work together, and that can be started by using a local service provider like us. If you have some design, print or signage needs, please refrain from obtaining these from online companies which are based overseas with their head office in a tax heaven, produced in China and paying no taxes in Australia. This is not helping our economy at all. You may have to pay slightly more but in the long run if everyone is working with local suppliers we will all benefit and make our great country even better than it was.

Since I started working in this industry in 1978 there has been constant technological changes, from design to print production.

We went from the hot metal typography on the Linotype machine; the film and offset printing technology; the first UNIX computers in 1984; the imagesetters; the Chromalins were replaced by the first digital proofers; drum scanners were replaced with digital scanners which soon became obsolete, replaced with digital cameras. Hot metal was killed by film technology, then film disappeared replaced by desktop publishing. Now some presses are not using DTP at all. Today almost everything can be produced digitally, however it’s not always the best way or the more economical option. It would take too long and be too technical to explain everything, but this is one of the reasons why we at DPPP have always been at the top of our trade, maintaining the traditions and the new technologies to always offer the perfect and most economical solution to our clients. We have always adapted to the latest technology and new opportunities.

In our last newsletter I announced the new Mimaki device, able to create some semi-3D points of sale for almost anything: spirits, champagne or wine bottles, handbags, shoes, creams, perfumes, you name it. With this same machine we can also do digital packaging, which means we can produce short runs of custom-made boxes, lunch boxes, etc. In partnership with a company based in the UK, we have the exclusivity of the technology to produce here in Australia this amazing point-of-sale in cardboard and other completely sustainable materials, which are also far more economical than the plastic-based models that are currently used in Australia.

I wish you all a great 2021, which can hardly miss being better than the previous one.

And last but not least, we have now reached the milestone of being 25 years in business here in Australia! And if we have been in business for that long, it also means that we must be better than good at what we are doing! I thank you all for being loyal clients, especially those who have been working with us for 20 years or more. That means a lot.

Yannick Gacoin

Director, JP

Best project of January

Once again I would like to thank the whole team of the Alliance Française de Sydney for their trust in us to handle the French Film Festival documents. From the flyers to the posters, tickets, envelopes, T-shirts, tote bags, pull-up banners and also all the 80-page programs which were different for each state with various quantities. All done and delivered in record time.

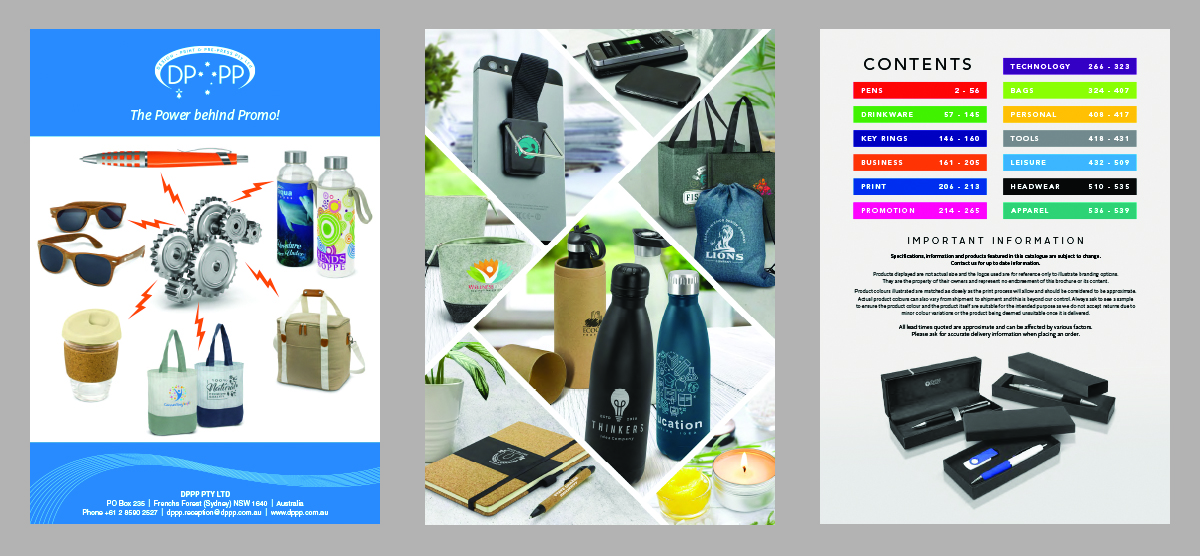

Promotionals

Website link to Promotional Catalogue

Recipe

Cranberry, Tomato & Thyme Crusted Rack of Lamb

Prep time

Serves

Ingredients

For the rosé wine and cranberry gravy:

1 garlic clove, crushed

1 bottle rosé wine

1 large sprig fresh thyme

4 tablespoons cranberry sauce

2 teaspoons caster sugar

25 grams butter

For the lamb:

2 garlic cloves

50 grams sun-dried tomatoes

3 tablespoons cranberry sauce

2 teaspoons fresh thyme leaves

salt and freshly ground black pepper

3 racks of lamb (6 cutlets on each) chined

Instructions

To make the gravy: put the garlic, rosé wine and thyme into a large pan, bring to the boil and boil rapidly for 15 minutes until reduced by half. Strain, discard the thyme and return the wine to the pan. Add the cranberry sauce and caster sugar and stir over a low heat until the sugar has dissolved. Set aside.

Preheat the oven to 200°C. Put the garlic, sun-dried tomatoes, cranberry sauce and thyme into a food processor and whizz together to a smooth paste. Season well with freshly ground black pepper.

Trim the lamb of most of the fat. Spread the cranberry mixture firmly onto the outer side of the lamb to coat evenly. Put crust side up into a roasting tin and roast in the middle of the oven for 20 minutes for medium-rare or 30 minutes for well done, covering the crust of the lamb loosely with foil if the crust starts to burn.

Remove the lamb from the oven and transfer to a warm plate and leave to rest in a warm place for 5 minutes. Meanwhile, pour the rosé wine mixture into the roasting tin and bring to the boil, scraping up all the pan juices into the gravy. Whisk in the butter until glossy. Season to taste.

Cut each rack of lamb into cutlets and serve with the rosé wine and cranberry gravy, creamy mashed potatoes and fine green beans.